We last left off with crashing the temperature of the wort in the boiler down to pitching temperature - around mid 20's oC.

I tend to leave the wort to settle so that the hops form a filter and keep most of the break material out.

While this is happening I would sort out my yeast. This time I'm using a dry yeast and a fairly neutral one to let the hops shine. It's Danstar Nottingham yeast, which I rehydrate in a few hundred mililitres of boiled / cooled water.

While this is happening I would sort out my yeast. This time I'm using a dry yeast and a fairly neutral one to let the hops shine. It's Danstar Nottingham yeast, which I rehydrate in a few hundred mililitres of boiled / cooled water.Rehydrating yeast involves sprinkling it onto the water and leaving for about 10 minutes, covered with some clingfilm. The yeast should not all sink to the bottom - if it does then suspect the health of the yeast batch. I tend to mix it back into suspension and see if it foams up after a further 15-20 mins. The clingfilm will rise and mist up if the yeast is viable. Give it a smell as well. You get an idea after a few times as to which yeasts are good or bad.

I also tend to recirculate the first few litres of wort to come from the boiler - similar to the recirculation done at sparging stage.

I also tend to recirculate the first few litres of wort to come from the boiler - similar to the recirculation done at sparging stage.Once the wort is running clear I let if run out of the boiler at height and fall into the fermenting bin underneath. This introduces plenty of oxygen into the wort - which is key to the yeat during the initial stages where it is multiplying like crazy.

It tends to foam up a bit as a result. I'll also give it a thrashing with a beer paddle to get as much air in as possible. Do you want a flake in that? :)

Now we're ready to pitch the yeast and put it away for fermentation. I try to ferment at a consitent 20 oC. I don't have a brewing fridge like some so I make do with moving the fermentor around or using a heating belt with a timer.

After a few hours the yeast starts to show signs of activity and evently a yeast head builds.

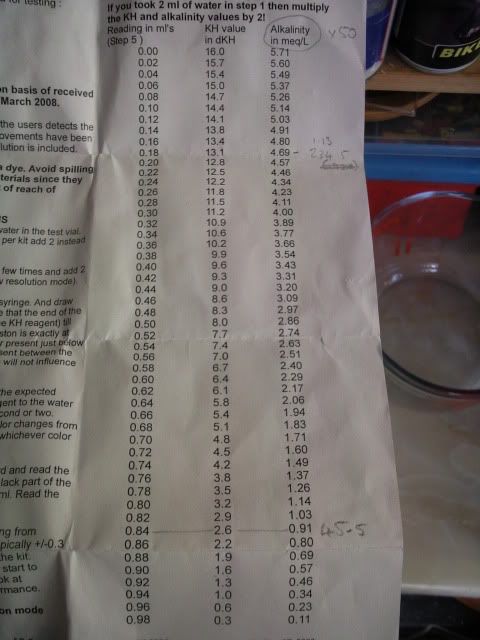

After a few days (3-5) this head dies down and the fermentation continues with less vigour. I tend to sterilise a hydromter at this point and drop it in so I can keep an eye on the specific gravity. Once down to below 1.014 and when I get 3 or more days at the same gravity then it's ready to bottle, although I leave it up to 2 weeks to allow the yeast a chance to do it's 3rd phase in the process of clearing up anything that might cause off flavours in the final beer.

Normally I keg most of the beer and bottle some. This time it's a competition brew so it's going in a mixture of bottles - 330ml glass. 500ml glass and 1ltr PET. This is a long process which I never look forward to. First they all need sterilising, then rinsing then priming.

Now I take a sample and then start filling the bottles.

The hop falvour and aroma is excellent with this brew. It is fairly clear and a reddish colour. Not as bitter as I thought - at least not a harsh astringent type of bitterness - which is good and what I was hoping for. It can only improve from now on and there is plenty of conditioning time before I need to send these off.

So it's wait a few weeks now and then have a sample to see how it's progressing. First samples suggest that this could be good but we'll have to wait and see!

.png)